KINFOLK - Visioneering Technologies Benefitting Humanity …

COMMERCIAL & INDUSTRIAL

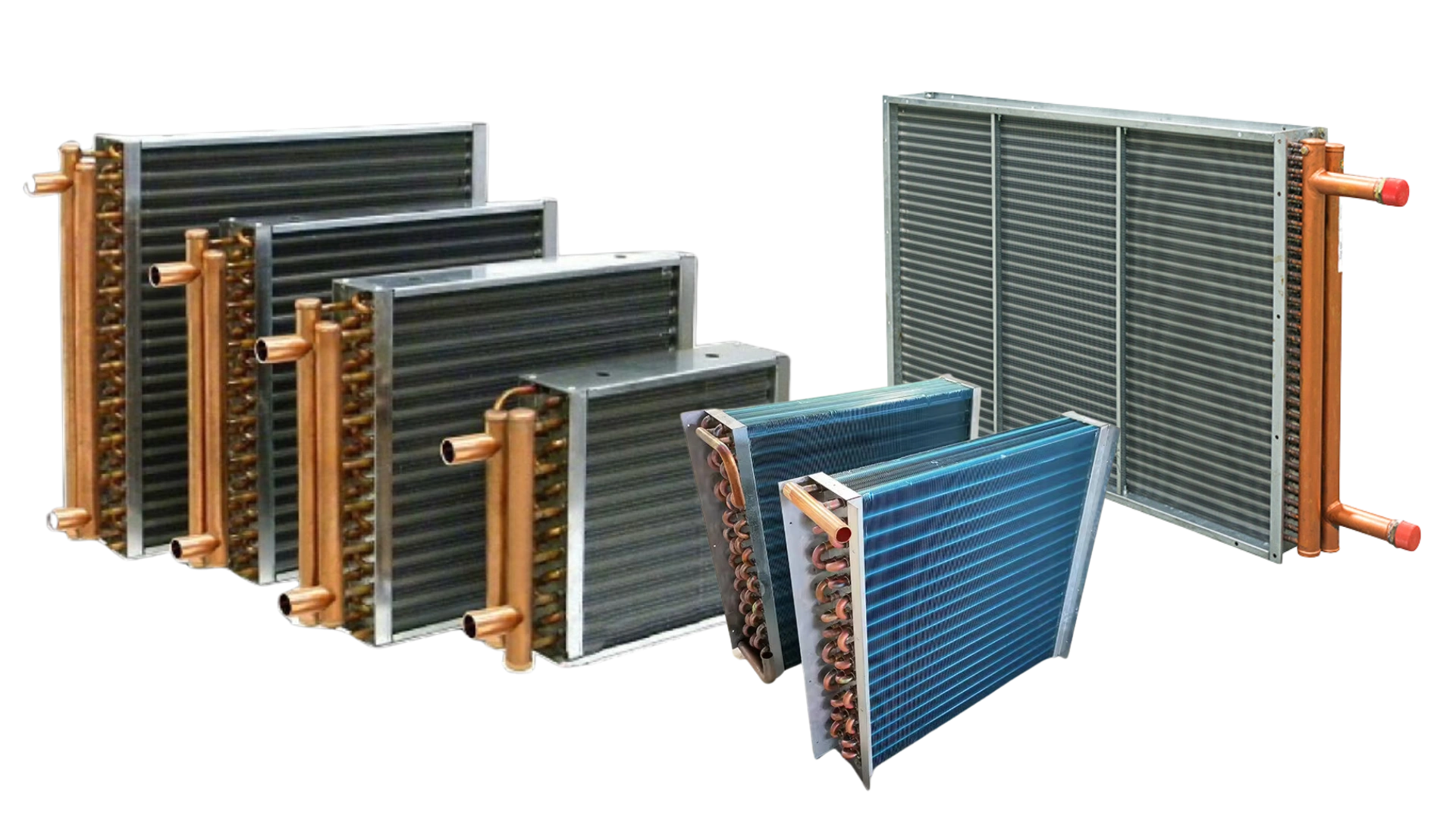

HVAC COILS

KINFOLK builds heat transfer coils of any size for your requirement for cooling and heating using chilled water, hot water, steam or refrigerant. We take up jobs for new requirement or replacement of existing coils

TYPE OF HEAT TRANSFER COILS

HIGH ENTHALPY CONFIGURATION (HEC) COILS

HIGH ENTHALPY CONFIGURATION (HEC) COILS

HIGH ENTHALPY CONFIGURATION (HEC) COILS

All cooling coils are intended to remove sensible heat and in the process it removes some moisture based on the psychrometric properties of the air. KINFOLK HEC coils are designed keeping the core psychrometric properties to target the maximum moisture removal from air as per the requirement for any process needs or storage needs. KINFOLK HEC coils are designed with optimal (less) air velocity across the coil, more surface area for maximum heat transfer and increased redundant time of air passing through the coil

EVAPORATOR COIL

HIGH ENTHALPY CONFIGURATION (HEC) COILS

HIGH ENTHALPY CONFIGURATION (HEC) COILS

KINFOLK DX evaporator coils are designed from 2 rows upto 10 rows with the widest range of circuiting control and splits available in practice. DX Coils are often used in Air Handlers or built up systems or just stand alone in ductwork. Often, multiple compressors are connected to the same DX coil and require capacity control. KINFOLK uses a intertwined circuiting to allow the use of full face area for uniform distribution of the refrigerant. In addition, you can also select from the face splits or row splits for 2, 3 or even 4 compressors on the same coil

CHILLED WATER COIL

HIGH ENTHALPY CONFIGURATION (HEC) COILS

CHILLED WATER COIL

KINFOLK Chilled water coils are designed from 4 rows upto 12 row with 1/2" or 5/8" copper tubes for both HVAC or process requirements. We are totally flexible in the design of coils and offer a wide range of circuiting patterns, fin spacings, rows and connection arrangements. The perfect coil design balances high efficiency performance with acceptable waterside and airside pressure drops. KINFOLK builds glycol coils for ethylene or propylene. Many of these applications are for process or heat recovery applications.

HOT WATER COIL

HOT WATER COIL

CHILLED WATER COIL

KINFOLK Hot Water coils are designed from 2 row upto 4 rows with 1/2" or 5/8" tubes made of copper or copper-alloy or SS. Hot Water Duct Booster Coils are built with either 1” flanges on all four sides for easy duct mounting or slip & drive casings for insertion into duct. These coils are also designed to maintain RH in industrial and process areas

STEAM COIL

HOT WATER COIL

CONDENSER COIL

KINFOLK Steam coils are designed from 1 row upto 4 rows with 5/8" or 1" tubes made of copper or copper-alloy or SS depending on the application. KINFOLK coils are designed in such a way that the condensate doesn’t collect in the coil. Most standard steam coils are opposite end connected and pitched within the casing to expedite condensate removal. It’s also possible to build same end standard steam coils

CONDENSER COIL

HOT WATER COIL

CONDENSER COIL

KINFOLK condenser coils are refrigerant based condensing coils for removing heat from the refrigeration circuit and letting out to the atmosphere. These are built with either 3/8“, 1/2” or 5/8” O.D. tubes and multiple wall thickness options. Available for multiple refrigerant condenser applications. These coils are available in the same or opposite end designs with a multitude of circuitry available. E-coating available upon request.

KEY FEATURES OF KINFOLK HVAC COILS

KINFOLK - Your Trusted HVAC Experts

- Custom-Engineered Design:

Each coil is designed based on airflow, capacity, and psychrometric conditions — ensuring maximum efficiency for every application.

- High-Performance Materials:

Uses premium seamless copper tubes and corrugated aluminum or copper fins for enhanced thermal conductivity and corrosion resistance.

- Optimized Fin Geometry:

Fin spacing from 8 to 14 FPI with precision louvering provides superior heat exchange while maintaining low air pressure drop.

- Durable Construction:

Rigid galvanized or stainless-steel casing with brazed joints and mechanical tube expansion ensures long-term structural integrity.

- Leak-Proof Assurance:

100% hydrostatic pressure-tested and nitrogen-checked for leaks up to 350 psi, guaranteeing safety and reliability.

- Flexible Applications:

Available for Chilled Water, DX Cooling, Hot Water, Steam, and Heat Recovery systems.

- Service-Friendly Design:

Easy access for cleaning and maintenance with drainable circuits and optional epoxy-coated fins for coastal or corrosive environments.

- Thermal Excellence:

Designed for maximum heat transfer efficiency and consistent performance even under fluctuating load conditions.

KEY FEATURES OF KINFOLK HVAC COILS

KINFOLK - Your Trusted HVAC Experts

Parameter

Specification Range / Details

Description

Type of Coils

Cooling / Heating / DX / Condenser / Heat Recovery

Designed for chilled water, refrigerant, or steam applications

Tube Material

Seamless Copper

High conductivity copper tubes for efficient heat transfer

Tube Diameter

3/8", 1/2", 5/8"

Selected based on air volume and thermal load

Tube Thickness

0.3 mm – 0.71 mm

Ensures durability and working pressure up to 350 psi

Fin Material

Aluminium / Copper

Corrugated fins for maximum air-side surface area

Fin Thickness

0.12 mm – 0.25 mm

Optimized for airflow and thermal performance

Fin Density

8 – 14 FPI

Customizable to balance heat transfer and pressure drop

Casing Material

GI / SS / Aluminium

Heavy-duty frame providing rigidity and corrosion resistance

Circuit Design

Single / Multiple / Interlaced

Designed as per flow requirement and refrigerant distribution

Testing Pressure

350 psi (Hydrostatic)

Each coil tested under nitrogen or water pressure

Working Pressure

Up to 300 psi

Suitable for chilled water and DX applications

Header Type

Copper / Brass

With threaded, flanged, or sweat-type connections

Surface Coating (Optional)

Epoxy / Heresite / Phenolic

For enhanced corrosion protection in coastal or chemical areas

Drainability

Complete Drain Design

Ensures condensate-free performance during shutdowns

Applications

AHUs, TFAs, Condensers, Heat Recovery Units

Ideal for industrial, commercial, and cleanroom HVAC systems

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.